Quikbuild 3D Panel

Head Office : Chennai

Branches : Delhi, Mumbai, Bangalore, Hyderabad, Chennai, Kochi, Vizag, Ahmedabad, Coimbatore

It is a Green Building Products company engaged in manufacturing and sales of prefabricated construction products for Clean Rooms, Cold Storages, Warehouses, Factories, Villas, Multi-storey residential & Commercial Buildings etc. The Company is Pioneer in developing 3D panels with expanded polystyrene core.

Financials With Revenue of 2.5Billions(2017-2018), company is expected to grow at 50% in next two years

About us Beardsell Ltd has built a reputation of reliability, and trust with its customers and other stakeholders over several decades. It is managed by a highly accomplished Board of Directors and a professional & competent management team.

Quick Build SystemThe Quick Build system uses modular panels that are prefabricated with utility add-ons to build a frame for the structure, Concrete or Plaster s then applied to the whole structure to complete it.

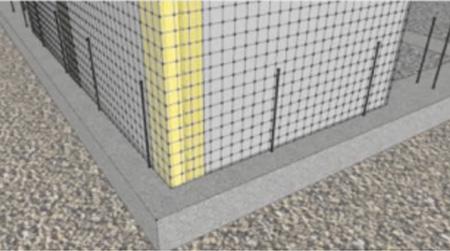

The panels consist of- A Polystyrene Core sandwiched between two engineered layers of

- Galvanized Steel Mesh in addition

- Galvanized Steel Truss is pierced through the Polystyrene Core and welded to each of the outer layer sheets of steel mesh.

The utility add-ons like electrical and water pipes can be pre-build into the core material or added in situ before applying the plaster or concrete.

Benefits of using this System- Modern Technology

- Insulated Building

- Increased Floor Area

- Green Building

- Stronger & Lighter

- Earthquake Resistance

- Design flexibility

- Crack Proof

- Low cost

Direct cost saving due to reduced labour, reduced material, and cheaper construction equipment. Low weight of the product also reduces logistical costs

Structural IntegrityThe monolithic structure of the panel in conjunction with concrete enables a structure build with it to withstand earthquakes, hurricanes, and high winds

About Quick Build ProductThe Quick Build Construction system uses Modular panels and accessories to build a frame for a structure. Concrete or Plaster is applied to these panels to finish the structure.

The panels consist of- Polystyrene Core

- Galvanized Wire Mesh - Two outer layers

- Galvanized Wire Trusses is pierced through the Polystyrene Core and welded to each of the outer layer sheets of Wire mesh.

- Groove (Approx. 2” deep) for Microbeam (with or without steel rod)

- Minimum Thickness of core in panel is 80mm

Tongue and Groove joint also available at ends

AccessoriesI-Mesh - Flat Joining Mesh

L-Mesh - Corner Joining Mesh Panel

C-Mesh - End Covering Mesh

Construction Method

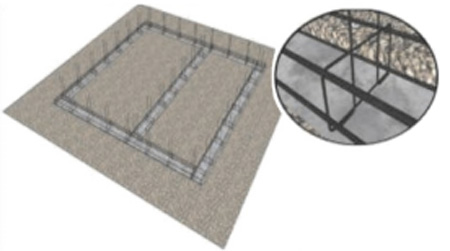

PLINTH BEAM- Providing steel reinforcement for plinth Beam.

- Re bars are providing at 2 feet span and 1” feet height.

- All along the plinth beam to hold the panels.

- Pour concrete to form the plinth beam.

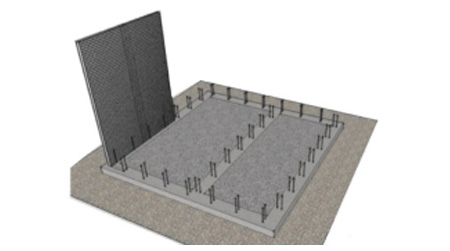

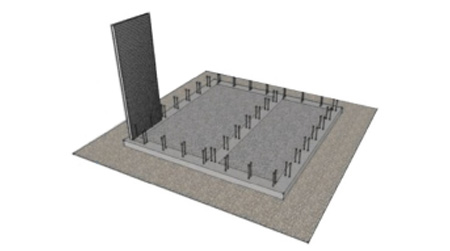

Panels are placed in between the re-bars on the plinth beam. Erected panels are then bound to the re-bars with binding wire.

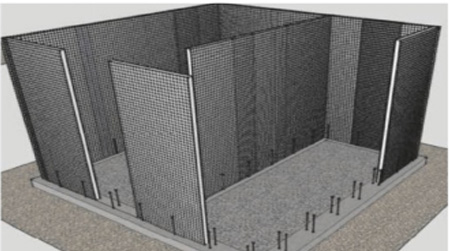

- Panels to Panel is Joined with a joining mesh

- I-mesh is used for a flat joint

- I-mesh is overlapped over the two panels and is bound with a binding wire or stapled using a Clinching Tool. At every 100mm span the joining mesh is bound to the panels.

Panels at the corners are joined with a L-mesh (Corner joining mesh). The Mesh is placed over the joint at the corner and is bound wire or stapled using a Clinching Tool to the panels. All corners of the building panels are joined from both inside and outside with the L-mesh

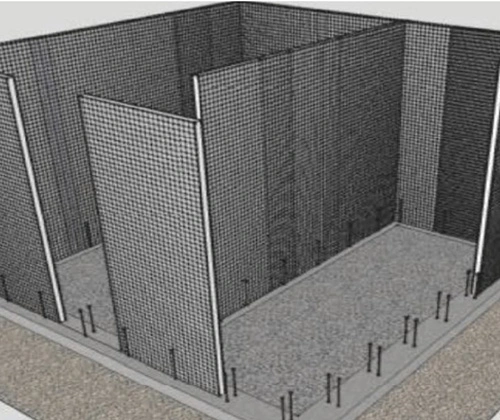

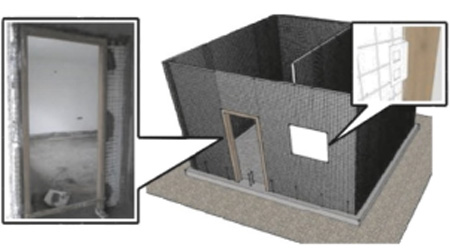

Complete erection of all wall panels leaving space for the doors or other opening.

- Cut opening for window with a help of a cutter.

- Fix door frame and window frame to its corresponding opening.

- Window frames are fixed with a help of a C-clamp.

- On one side it is screwed to the wooden frame and the other end is fastened to the panel with Binding wire.

- Piping is placed in the core material behind the Wire Mesh

- No Chipping and Rework required afterwards

Erect the Roof Panels on the walls and join them using L-mesh on all the corners where wall panel and roof panel meet. L-mesh should be on inner and outer side of corners.

Plaster both sides of the wall panels with mortar. The plastering can be applied Manually or with a Shotcreting machine. First coat a plaster called rough plaster is 15 mm thick up to mesh level.

Shuttering plates support at every 1 feet distance in only one direction is used for Roof Casting. Slab top Concreting is 3 inches and Slab bottom plastering 1 inch.